Explore the Latest in Packaging Innovation @ Pack Expo Chicago! Nov 3-6, 2024 | Booth #S-3620

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn more- Home

- Videos

- Vertical Form Fill Seal Machines

- Matrix Apollo™ Servo-Driven Intermittent High Speed bagger

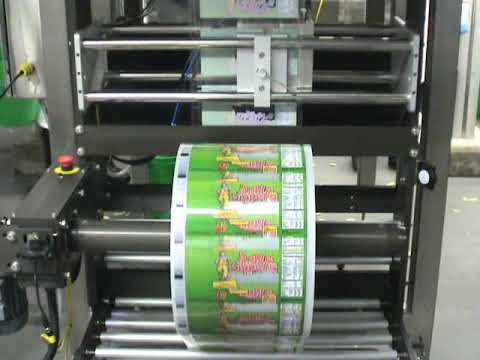

Matrix Apollo™ Servo-Driven Intermittent High Speed bagger

Watch the Matrix Apollo servo driven intermittent high speed bagger in action. This fast machine offers high packaging speeds while accommodating numerous bag styles, including flat bottom and gusseted style. It features Matrix’s advanced servo motion control of the film pull belts and the end-seal jaws for smoother and faster operation than ever before.

Mike Crummy, an engineer at Matrix Packaging Machinery, introduces the new features of the Apollo machine.

One of its standout features is the ability to quickly set up the machine, significantly reducing changeover time and downtime. We’ve incorporated automatic controlled axes in critical motion areas, such as the forming tube. When the forming tube is changed, the machine can revert to the original settings, eliminating the need for tools and reducing the risk of costly mistakes during setup. This not only saves time and money but also minimizes wasted packaging film.

These features are controlled through the touchscreen interface. Each recipe contains data for the axes positions, which can be adjusted in real time during operation to optimize for varying conditions throughout the packaging day. Once optimized, the settings are saved in the recipe for easy retrieval. The axes use small servo motors, providing powerful, repeatable, and reliable motion positioning.

At the rear of the machine, we have axes to set up the registration position, a critical function for printing on bags. The registration can be adjusted forward, backward, left, or right using the same servo motor technology. Additionally, the edge guide system employs a small drive unit to control the film's position relative to the former for automatic positioning. During a changeover, the system moves into the correct location once new tooling is in place, saving the operator considerable time.

These innovations make the Apollo machine more efficient and user-friendly, helping to optimize the packaging process and reduce downtime.

Additional Videos

Watch as Matrix Packaging and Marjon Foods collaborate to package a variety of fruits, vegetables, and stir fry starters. This video highlights the benefits of using Matrix Equipment to package fresh produce people love to eat!

Coffee Support is a packager of ground and whole bean coffee under their own brand name as well as a contract manufacturer.

Steve McConnell talks about the Matrix Bag-in-Bag, kit's features, benefits and why it might be the perfect fit for your product.

Watch as our Mercury makes 2 different sized pillow bags and 2 combinations of rice mixtures. Fast, Easy, and Efficient.

The small footprint dual Morpheus VFFS continuous machine is capable of packaging 130 5oz bags of frozen cheese curds with accuracy.

Watch as these Dual Morpheus VFFS machines paired with a Yamato scales produce 260 bpm of frozen cheese curds.

Watch as our robust Morpheus and Yamato scale packages convenient pillow bags of 100 grams of dried pasta!

Watch as our robust Morpheus and Yamato scale makes quick work of packaging small bags of yummy treats!

The Matrix Morpheus continuous motion vertical form fill seal machine packages 17 grams of cereal in a pillow bag.

The continuous motion Morpheus bags corn muffin mix in flat-bottom gusseted bag. This vertical form fill seal machine is flexible and efficient to create a secure seal for gusseted bags.

Watch as our robust Morpheus and Yamato scale makes quick work of filling bags for sample dog food treats!

Watch the Morpheus with Allen-Bradley controls combined with a Spee-Dee auger run 2.5oz bags of ground coffee at 120 bpm. This innovative technology creates high speed solutions.

Combining a pillow bag with 1.5 ounces of ground coffee with the Spee-Dee Auger and WIPOTEC check-weigher, the Matrix Morpheus is effective and quick.

Join Chris Higgins as he discusses the benefits of the Matrix Mercury intermittent flexible packaging machine. Chris shows the versatility of this machine as it produces pillow bags

Combining the Morpheus with Spee-Dee volumetric cup filler allows for quick production of 3 ounce bags of raw nuts at 120bpm. This vertical form fill seal machinery utilizes SmartGate technology.

This video showcases coffee packaging on the Morpheus continuous motion vertical form fill seal machine.

The Matrix Morpheus XL makes quick work of packaging these IQF patties into nice family sized bags of 3.6 ounces running at 55 bpm.

The Morpheus XL is available using a maximum 15" wide bag width. This form fill seal machine packages IQF sausage patties with consistent ease.

See an in-depth video on the Matrix Morpheus from Pack Expo Connects. This machine features innovative technology, including either Allen-Bradley controls or the state-of-the-art Beckhoff control system.

The Morpheus packages your product with efficiency and flexibility. This machine is diverse to accommodate endless industries for a wide range of applications, including food, non-food, frozen, and more.

The Matrix Mercury Twin makes quick work of producing pillow bags in a small footprint.

Watch the Matrix Mercury running fresh radishes in a 1# bag at 58bpm. The Matrix Mercury is a vertical form fill seal machine designed to efficiently packaging a wide variety of products.

Combining the Matrix Mercury and a Yamato 14 head scale with Pro-Surveil makes producing these sunflower seeds simple and seamless. The Matrix Mercury is versatile for diverse snack food applications.

The Matrix Mercury produces 5# Freezer Gel Packs with consistency and ease. These large freezer packs measure 8" x 12".

The Matrix Mercury produces consistent convenient gel/freezer packs at 50 bpm! This high speed vertical form fill seal machinery provides diverse industries with efficient solutions.

The Matrix Mercury a intermittent vertical form fill machine, packages cell phone ring holder stands in film that is commercially compostable!

The Matrix Mercury successfully packages 1# pillow bags of powdered detergent. This vertical form fill seal machine is flexible and efficient.

The versatile Mercury packaging machine makes quick work by bagging fresh cheese curds at 45 bags per minute.

The Matrix Mercury consistently packages fresh pineapple at 45 bpm. This vertical form fill seal machine can package single servings of fresh fruit in a pillow style bag.

Meet the Elete Tilt Vertical Form Fill Seal Machine. 0-60 degrees in seconds and you're ready to roll! This system is an intermittent vertical form fill seal system designed for gentle, efficient packaging.

The Matrix Elete vertical form fill seal machine is designed to bag Coffee Beans with the featured de-gassing valve and label.

Watch the Matrix Elete with a twist! See this Elete with an Angled jaw to create an easy to snip and squeeze option. Versatile to accommodate unique product requirements, this vertical form fill seal machine is efficient and flexible.

View our Elete Premier with Benchmark conveyor, WIPOTEC checkweigher and Spee-Dee Auger to package parmesan cheese in large pillow bags.

Watch the vide and get a glimpse of the Matrix Elete Premier easily producing large 10"x14" pillow bags that are made of 100% recyclable film. These large bags are idea for industries that require a more sustainable solution.

Watch the Matrix Elete vertical form fill seal system integrated with a Spee-Dee cup filler package 4# of coffee beans consistently at 50bpm.

See the Matrix Elete create a 3 sided seal using a rotated jaw. This unique technology allows the Matrix Elete to create a tight, secure seal.

Learn more about the Elete Premier 18/20 sanitary VFFS bagger. This vertical form fill seal machine creates 14 inch pre-applied zipper pouches, running at 15 bpm.

Watch the Matrix Elete machine with a rotated jaw packaging trail mix and pumpkin seeds at 60 bpm. Working on a variety of industry applications, the Matrix Elete is efficient and reliable.

Matrix Bag-in-Bag packages ground coffee with filter paper and a foil master bag. This vertical form fill seal system is easy to run and maintain.

The Matrix Bag-in-Bag packages ground coffee quickly and effectively, providing easy-to-use options for commercial markets.

See an in-depth video on the Matrix Bag-in-Bag from Pack Expo Connects. This vertical form fill seal solutions features innovative technology.

Pillow bags are produced in the upper section and drop down into an overwrap package (pillow or optional flat bottom or gusseted bags) produced on the lower section of the machine.

This system provides an innovative solution to multiple products in an over-bag.

Check out the Auto Set Eye Feature video features on the vertical form fill seal machines. This demonstration video shows different settings of the auto set eye technology.

Matrix offers vertical form fill seal machinery to bag Ice berg, romaine, spring, and other lettuce mixes. Our VFFS machines can package your salad shreds and mixes salads efficiently.

Large gusseted bag of whole coffee beans are bagged on VFFS with valve. This solution is quick and effective, creating lasting results.

See peeled apple wedges bagged on VFFS machinery from Matrix. These single serving packages are perfect for on-the-go or busy families.

Watch the Matrix Mercury Twin Bagging fresh green beans. This vertical form fill seal machine runs at high speeds to create higher throughput and maximum efficiency in production.

Change from pillow bags to a modified doy and back with the simple switch of your jaw system.

Watch this video to see one solution Matrix can provide. A fully functioning packaging line in a small footprint.

Producing five-pound shredded lettuce bags up to 25 bags per minute, the Elete DS 13 vertical form fill seal system works quickly to create a secure seal.

The Matrix MVI-280 (Mercury) is a vertical form fill seal solution designed to bag a wide range of products. In this video, green beans are being bagged on the Single Mercury.

Watch the Matrix Mercury Single and Twin running bags of green beans at 30 and 60 bpm to the tune of Jingle Bell Rock.

Ultrasonic welding applies precise ultra-high-speed vibrations along a seam. Ultrasonic welding is quick and precise, forming a high quality seal with superior mechanical strength.

Watch this video to see a half dozen Orion vertical form fill seal machines hard at work bagging candy and confectionery products.

The Matrix Elete DS-13 Quad vertical form fill seal machine is a high quality system designed for four side sealed flat bottom bags. In this video the Quad is bagging coffee.

The Matrix Elete is a high performance, totally configurable solution for larger bags. This system works at high speeds to create a quality seal in each application.

The Matrix Morpheus is a vertical form fill seal machine capable of speeds of up to 180 bags per minute. This system provides complete control for manufacturers.

Watch Our Matrix Mercury On-Demand Video from Pack Expo Connects. This vertical form fill seal system is designed to be tough, durable, and reliable for endless use.

Snack food executives and operators discuss the winning recipe to bagging 8 million bags this year

Matrix working in conjunction with Spee-Dee to provide what Chauvin Coffee needs.

See an in-depth video on the Matrix Elete Premier from Pack Expo Connects. The Matrix Elete Premier is a hygienic stainless-steel machine made of 95% stainless steel.

The Matrix Pro specializes in high speeds and flexibility for unprecedented production. This machine is an intermittent vertical form fill seal solution designed for diverse applications.

The Pro Custom vertical form fill seal machine specializes in providing innovative solutions to challenging applications. This system features a standard automatic film tracking system.

Watch the integrated Filler and VFFS machines bag food products, like seasoned croutons. The Apollo bagging machine is an efficient and effective bagging system.

Change bag sizes and widths as well as bag style depending on the product or application you are running at the moment.

Experience the Ultimate Efficiency: Matrix MVI-330S Paired with Yamato ADW-0-1214S for Vibrant and Fresh Sweet Pepper Packaging.

Experience the Ultimate Efficiency: Matrix MVI-330S Paired with Yamato ADW-0-1214S for Packaging Crisp, Fresh Broccoli.

Matrix and Yamato seamlessly integrate to deliver the most accurate weight and your desired packaging

Discover the ultimate spinach packaging solution with the Matrix MVI-330S and Yamato ADW-0-1214S duo! Streamline your spinach packaging process with features like high-speed sealing, precise temperature control, and versatile bag sizes. Trust in durability, reliability, and efficiency for your fresh spinach packaging needs!

Unlock peak efficiency in packaging leafy greens with the Matrix MVI-330S. Explore cutting-edge features tailored for streamlined and precise packaging, ensuring freshness and reliability every time.

Experience the ultimate versatility in produce packaging with the Matrix MVI-330S and Yamato ADW-0-1214S duo. As we show a seamless operation as a variety of fresh produce is expertly packaged, showcasing the reliability, efficiency, and precision of this advanced packaging solution.

Step into the future of liquid packaging with our groundbreaking MVC-300L continuous motion Vertical Form Fill Seal (VFFS) Machine. Discover unparalleled efficiency, precision, and versatility for beverages, soups, sauces, gels, and more. Join us on a journey of innovation and excellence in liquid packaging!